Product Code : 3D-C103-CU-PO1

Niobium Alloys Powder is used in aerospace and defense propulsion applications requiring strength at sustained high operating temperatures. Niobium Alloys Powder is now offered in spherical powder for use with the electron beam, laser powder bed, direct energy deposition, and cold spray technologies for additive manufacturing of complex geometries.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

| Spherical C103 Powder | 3D-C103-CU-PO1 | Customized | 0-15μm | |

| Spherical C103 Powder | 3D-C103-CU-PO2 | Customized | 15-53μm | |

| Spherical C103 Powder | 3D-C103-CU-PO3 | Customized | 45-105μm | |

| Spherical C103 Powder | 3D-C103-CU-PO4 | Customized | 75-150μm | |

| Spherical C103 Powder | 3D-C103-CU-PO5 | Customized | Customized |

Synonyms

Niobium C103, ASTM B540, Paliney 7, Nb-Hf-Ti, HfNbTi, NbHfTi

ASTM B652

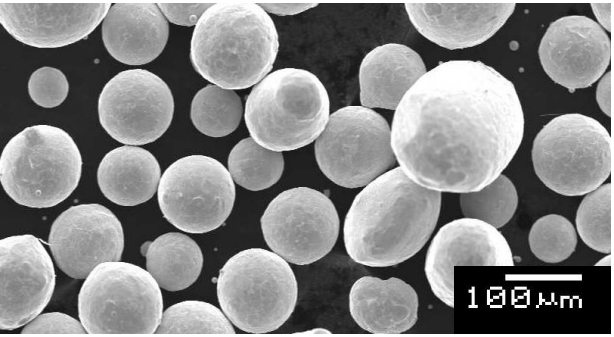

High purity (≥99.9%)

low oxygen,

high sphericity

smooth surface

No satellite spheres,

uniform particle size distribution,

and excellent flow properties,

And high bulk density and tap density.

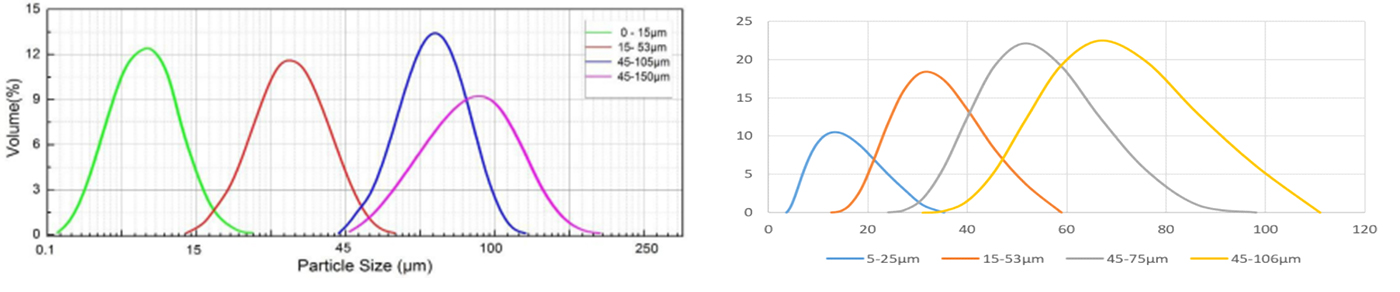

Niobium C103 Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 45-150μm, 75-150μm.

Spherical Powder is offered in fine and coarse sizes. Fine is defined as nominal +15µm/-50µm with coarse being defined as +50µm/-180µm.

(Various granularities can be customized according to customer requirements)

Laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

Direct laser deposition (DLD)

Powder hot isostatic pressing (HIP)

Metal injection molding (MIM)

Powder metallurgy (PM)

Laser cladding (LC), etc.

| Element | Minimum weight % (Coarse) | Maximum weight % (Coarse) | Minimum weight % (Fine) | Maximum weight % (Fine) |

| Ti | 0.7% | 1.3% | 0.7% | 1.3% |

| Hf | 9% | 11% | 9% | 11% |

| Zr | <0.7% | <0.7% | ||

| W | <0.5% | <0.5% | ||

| Ta | <0.5% | <0.5% | ||

| O | <0.025% | <0.0325% | ||

| N | <0.01% | <0.01% | ||

| C | <0.015% | <0.015% | ||

| H | <0.0015% | <0.0015% | ||

| Nb | Balance | Balance |

| (Coarse) | (Fine) | ||

| Density | g/cm3 | ~5.2 | ~4.8 |

| Form: | Powder | ||

| Color: |

| Property | Coarse | Fine |

| Nominal PSD(um) | 50-180 | 15-50 |

| D10(um) | 53-65 | 20-30 |

| D50(um) | 85-99 | 30-40 |

| D90(um) | 155-175 | 40-50 |

| Hall Flow(sec/50g) | <15 | Does Not Flow |

| Apparent Density (g/cm3) | >5 | - |

Niobium alloys powder have a wide range of applications in various industries. Here are some common uses of niobium alloys powder:

Aerospace industry: Niobium alloys powder is used to make high-strength and lightweight parts for aircraft, rockets, and satellites. It can also be used as a heat shield for spacecraft.

Medical industry: Niobium alloys powder is biocompatible and non-toxic, making it suitable for use in medical implants and devices such as pacemakers, dental implants, and joint replacements.

Energy industry: Niobium alloys powder is used in nuclear reactors and superconducting magnets for energy generation and transmission.

Automotive industry: Niobium alloys powder is used to produce high-strength, low-weight components for automotive engines, exhaust systems, and suspension systems.

Electronics industry: Niobium alloys powder is used to produce capacitors for electronics devices such as mobile phones, computers, and televisions.

Sports equipment: Niobium alloys powder is used to make high-performance sports equipment such as golf clubs, tennis rackets, and bicycle frames.

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Packaging

Standard Packing: Vacuum packaging, 1 kg/bag or 2 kg/bag. Iron drums lined with a plastic bag, 25 kg/drum. Special package is available on request.

| Linear Formula | Nb-89% Hf-10% Ti-1% |

| MDL Number | N/A |

| EC No. | N/A |

| Pubchem CID | 19751102 |

| IUPAC Name | hafnium; niobium; titanium(2+) |

| SMILES | [Ti+2].[Nb+2].[Hf+4] |

| InchI Identifier | InChI=1S/Hf.Nb.Ti/q+4;2*+2 |

| InchI Key | YZMOKPJTVNUKTK-UHFFFAOYSA-N |