Product Code : 3D-Inconel625-CU-PO1

Spherical Inconel 625 Powder is a Ni-based alloy powder with outstanding corrosion resistance for 3D metal printing. It is a nickel-chromium-molybdenum-niobium alloy. Service temperatures from cryogenic to 982°C.

Inconel 625 is a nickel-based superalloy that possesses high strength properties and resistance to elevated temperatures. It also demonstrates remarkable protection against corrosion and oxidation. Its ability to withstand high stress and a wide range of temperatures, both in and out of the water, as well as being able to resist corrosion while being exposed to highly acidic environments makes it a fitting choice for nuclear and marine applications. Typical applications are seawater components, flare stacks, aircraft ducting systems, specialized seawater equipment, chemical process equipment, turbine shroud rings, engine thrust-reverser systems, jet engine exhausts systems.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Nickel Based Inconel 625 Spherical Powder Synonyms

INCO 625

Nickel Based Inconel 625 Spherical Powder Particle Size

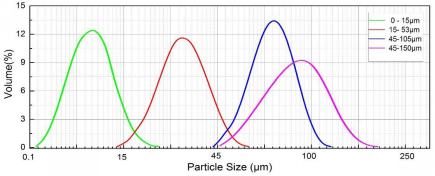

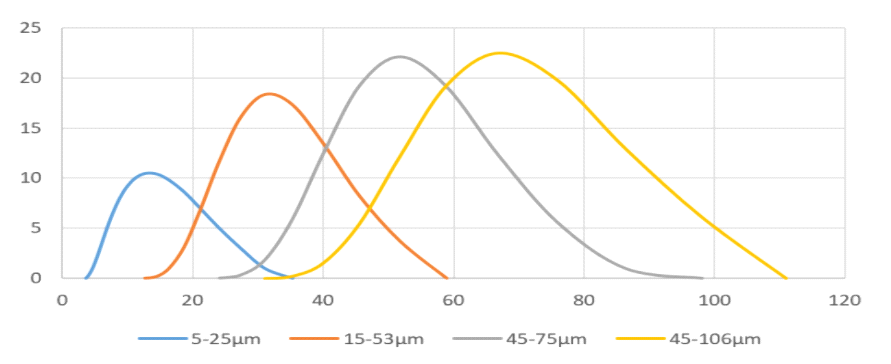

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Nickel Based Inconel 625 Spherical Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

IN625 Spherical Powder Characteristics

Chemical Composition [ wt.% ]

Element Min Max

Cr 20.0 23.0

Mo 8.0 10.0

Nb+Ta 3.15 4.15

Fe 5.0

Ni Balance Balance

Nickel Based Inconel 625 Spherical Powder Applicable Processes

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder thermal and other static pressure forming (HIP), metal injection forming (MIM), powder metallurgy (PM), laser melting application (LC), etc.

Spherical Copper-coated Tungsten (W-Cu) Powder Application

Typical applications are seawater components, flare stacks, aircraft ducting systems, specialized seawater equipment, chemical process equipment, turbine shroud rings, engine thrust-reverser systems, jet engine exhausts systems.

Packing of Nickel Based Inconel 625 Spherical Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Nickel Based Inconel 625 Spherical Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.