Product Code : 3D-Inconel718-CU-PO1

Inconel718 alloy is a precipitation hardening nickel-chromium-iron alloy containing niobium and molybdenum. It has high strength, good toughness, and corrosion resistance in high and low-temperature environments below 650°C. Its state can be solid solution treatment or precipitation hardening state.

Inconel 718 is a high-strength, corrosion-resistant nickel-chromium material used in a wide temperature range from cryogenic to high-temperature applications. The age-hardenable alloy can be readily fabricated, even into complex parts. Its welding characteristics, especially its resistance to post-weld cracking, are outstanding. The ease and economy with which IN718 can be fabricated, combined with good tensile, fatigue, creep, and rupture strength, have resulted in its use in a wide range of applications. Examples of these are components for liquid-fueled rockets, rings, casings, and various formed sheet metal parts for aircraft and land-based gas turbine engines, and cryogenic tankage. It is also used for fasteners and instrumentation parts.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Inconel 718 Spherical Powder Synonyms

IN718, Inconel-718, DMLS Nickel, 40-47 HRC, 370-450HB, UNS N07718

Inconel 718 Spherical Powder Characteristics

Chemical Composition [ wt.% ]

Element Min Max

Ni 50.0 55.0

Cr 17.0 21.0

Nb 4.75 5.5

Mo 2.8 3.3

Ti 0.65 1.15

Al 0.2 0.8

Fe Balance Balance

| Chemical Composition (wt%) of Inconel 718 | ||||||||||

| Item | Fe | C | Mn | Si | Ni | Cr | Mo | V | W | Al |

| In718 | Bal. | ≤0.08 | ≤0.35 | ≤0.35 | 50.0~55.0 | 17.0~21.0 | 2.8~3.3 | - | - | 0.2~0.8 |

| Mg | Cu | Ti | Nb | Zr | P | S | Co | |||

| ≤0.01 | ≤0.3 | 0.65~1.15 | 4.75~5.5 | - | ≤0.015 | ≤0.015 | ≤1.0 | |||

Oxygen≤400 ppm; Nitrogen≤300 ppm

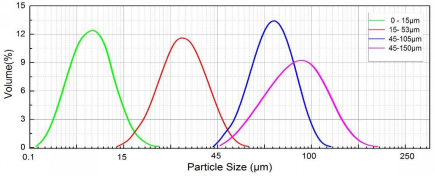

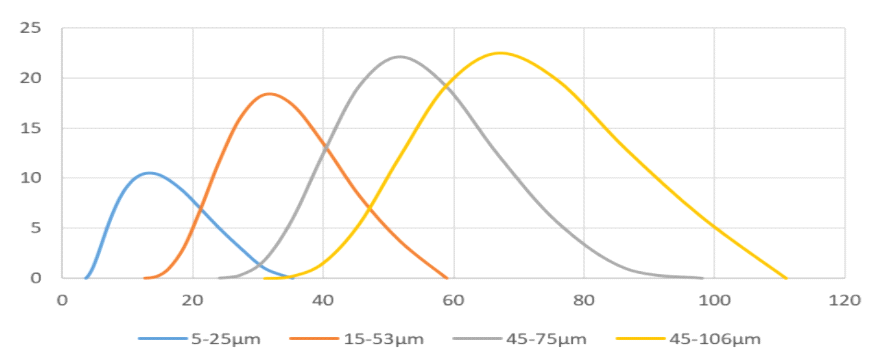

Inconel 718 Spherical Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Nickel Based Inconel 718 Spherical Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Standard Specification

| Nickel Base Alloy Powder | Composition (%) | O (%) | A.D.g/cm3 | Particle Size | ||

| Inconel 718 | Ni50-55,Cr17-21,Mo2.8-3.3,Nb+Ta4.75-5.5, | 0.05-0.1 | 3.8-5.0 | 15-45um, 20-63um, 45-150um D50 10-15um, D50 1-2um, D50 0.5-1um. | ||

| Inconel 625 | Cr20-23, Mo8-10 | |||||

| Hastelloy X | Cr20.5-23, Mo8-10, Fe17-20 | |||||

| Hastelloy C | Cr15-16.5, Mo15-17, Fe40,W3-4.5,Co1.5-2.5 | |||||

| Invar | Ni35-37,Fe Bal | 3.5-4.5 | ||||

| Kovar | Ni28.5-29.5, Co16.8-17.8, Fe BalCu3-5, | 3.0-4.5 |

Nickel Based Inconel 718 Spherical Powder Applications

- Additive Manufacturing (3D printing)

- Metal Injection Moulding (MIM)

- Cold and Hot Isostatic Pressing (CIP and HIP)

- Coatings

Nickel Based Inconel 718 Spherical Powder Applicable Processes

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder thermal and other static pressure forming (HIP), metal injection forming (MIM), powder metallurgy (PM), laser melting application (LC), etc.

Packing of Nickel Based Inconel 718 Spherical Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Nickel Based Inconel 718 Spherical Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.