Product Code : 3D-Co-CU-PO1

Cobalt is an important raw material for the production of heat-resistant alloys, hard alloys, anti-corrosion alloys, magnetic alloys and various cobalt salts. Cobalt-based alloys can be used as blades, impellers, pipelines, jet engines, rocket engines, missile components, various high-load heat-resistant components in chemical equipment, and important metal materials in the atomic energy industry. As a binder in powder metallurgy, cobalt can ensure the toughness of cemented carbide.Spherical cobalt powder can be used in thermal spraying, powder metallurgy, electronics industry, petrochemical industry and other fields.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Synonyms

Co spherical particles, cobalt spherical powder

Spherical Cobalt Powder Characteristics

High purity (99.9% min.)

Low oxygen (can be less than 600 ppm)

High sphericity (90% min.)

Smooth surface, no satellite

Uniform particle size distribution, excellent flowability (Hall Flow Rate ≤12.0 s/50 g)

High bulk density (≥5.0 g/cm3) and tap density (≥ 6.0 g/cm3)

Spherical Cobalt Powder Particle Size

Laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

Direct laser deposition (DLD)

Powder hot isostatic pressing (HIP)

Metal injection molding (MIM)

Powder metallurgy (PM)

Laser cladding (LC), etc.

Spherical Cobalt Powder Chemical Composition

| Chemical Composition by ICP-AES: | Wt % |

| Co | Remainder |

| Fe | <0.005 |

| Al | <0.002 |

| Cu | <0.001 |

| Mo | <0.003 |

| Si | <0.002 |

| Ni | <0.002 |

| Ta | <0.05 |

| W | <0.005 |

| Gas Impurities | |

| O | ≤0.06 |

| N | ≤0.005 |

| C | ≤0.01 |

Spherical Cobalt Powder Physical Properties

| Form: | Powder | |

| Color: | Black grey | |

| Melting Point: | 1495°C | |

| Boiling Point: | 2900°C | |

| Density: | 8.9 g/cm3 | |

| Density (g/cm3) | Hall Flow Rate (s/50g) | |

| Apparent Density | Tap Density | Value |

| >5.0 | >6.0 | </= 12.0 |

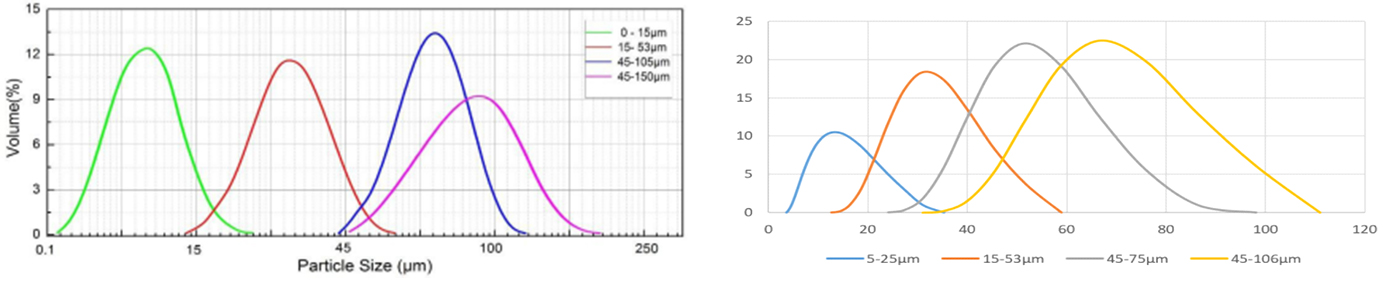

Spherical Cobalt Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

(Various granularities can be customized according to customer requirements)

Standard Packing

Vacuum packaging, 1 kg/bag or 2 kg/bag. Iron drums lined with a plastic bag, 25 kg/drum. Special package is available on request.

Chemical Identifiers

| Linear Formula | Co |

| MDL Number | MFCD00010935 |

| EC No. | 231-158-0 |

| CAS | 7440-48-4 |

| Beilstein/Reaxys No. | N/A |

| Pubchem CID | 104730 |

| SMILES | [Co] |

| InchI Identifier | InChI=1S/Co |

| InchI Key | GUTLYIVDDKVIGB-UHFFFAOYSA-N |