Product Code : 3D-CoCrWMo-CU-PO1

Spherical CoCrWMo Alloy Powder is a new type of material that is always used for medical purposes, such as Metal (inner) crowns, fixed bridges, removable local denture support, and stuck ring.

CoCrWMo alloy has been widely used due to its excellent thermal strength performance, corrosion resistance, and wear resistance, and is even irreplaceable in some harsh working conditions, such as the nuclear energy industry, gas turbine industry, medical field, and aerospace industry.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

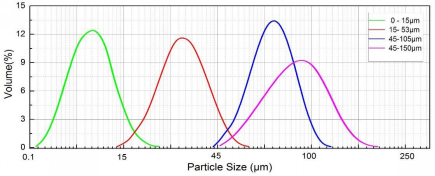

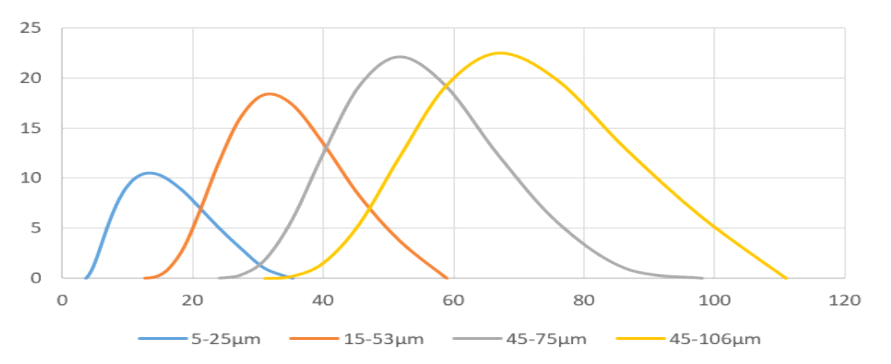

Spherical CoCrWMo Alloy Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Spherical CoCrWMo Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical CoCrWMo Alloy Powder Specifications

| Product | CoCrWMo | ||||

| PSD μm | 15-45 | 15-53 | 45-106 | 45-150 | |

| Laser PSDμm | D10 | 27-32 | 29-34 | 48-53 | 53-58 |

| D50 | 40-45 | 48-53 | 73-78 | 86-92 | |

| D90 | 62-67 | 72-76 | 115-120 | 142-147 | |

| Hall Flow s/50g | 11-14 | 11-14 | 11-14 | 11-14 | |

| Apparent Density g/cm3 | 5.0-5.2 | 5.0-5.2 | 5.0-5.2 | 5.0-5.2 | |

| Chemical Composition | Co:64.0-66.0; Cr:24.0-26.0; W:4.0-6.0; Mo:4.0-6.0; Si≤1.0 | ||||

| Industry | Biomedical | ||||

Spherical CoCrWMo Alloy Powder Processing Methods

- Gas Atomization(GA)

- Plasma Rotating Electrode Process(PREP)

Spherical CoCrWMo Alloy Powder Application

CoCrWMo alloy has been widely used due to its excellent thermal strength performance, corrosion resistance, and wear resistance, and is even irreplaceable in some harsh working conditions, such as the nuclear energy industry, gas turbine industry, medical field, and aerospace industry.

Packing of Spherical CoCrWMo Alloy Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical CoCrWMo Alloy Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.