Product Code : 3D-Fe-CU-PO1

Iron powder is a kind of important metal powder for powder metallurgy, and it requires a large quantity of Fe powder accounts for 85% of the total metal powder. Iron powder is mainly used in manufacturing machine parts.

Iron-based alloy powder can be used on the working layer of abrasion-resistant anticorrosive parts, such as hydraulic turbine blade, nozzle, wearing ring, hydraulic rod. The stainless steel powder has a good sphericity configuration with low oxygen content, high hardness, and good toughness.

ATT can supply different kinds of Iron-Based Alloy Powder in high purity. If you can't find the sizes or compositions you need, please contact us by email. We have customized sizes and compositions according to customer's requests.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Spherical Iron Based Alloy Powder Specifications

Grade:

Stainless steel powder: 304, 316L, 410L, 15-5PH, 17-4PH, 2Cr13

High-strength steel powder: A100, 300M, 30CrMnSiA, 40CrMnSiMoVA

Tool steel powder: 18Ni300, H13, M2, M35, M42, T15, 2030, S390

Iron-nickel alloy powder: Invar 36

Standard: GB/T 3077, GB/T 1299, GB/T 1480, GB/T 5329, GB/T 8180

Particle size: 0-20μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm

Shape: Spherical, Ψ0≥0.85

Appearance: Gray

3D Printing Application: SLM, LMD

Other Application: PM, MIN, HIP, SP, welding repair

Chemical Composition of Iron Based Alloy Powder

| Grade | Chemical Composition (wt.%) | ||||||||||||||||

| C | Cr | Ni | Mn | Mo | Si | Nb | Cu | Co | Ti | Al | V | P | O | N | S | Fe | |

| 304 | ≤0.07 | 17-19 | 8-10 | ≤2 | ≤1 | ≤0.035 | ≤0.03 | Bal. | |||||||||

| 304L | ≤0.03 | 18-20 | 8-10 | ≤2 | ≤1 | ≤0.035 | ≤0.03 | Bal. | |||||||||

| 316 | ≤0.08 | 16-18.50 | 10-14 | ≤2 | 2-3 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||

| 316L | ≤0.03 | 16-18 | 12-15 | ≤2 | 2-3 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||

| 410 | ≤0.15 | 11.5-13.5 | ≤1 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||||

| 420 | 1.06-0.25 | 12-14 | ≤1 | ≤1 | ≤0.035 | ≤0.03 | Bal. | ||||||||||

| 430 | ≤0.12 | 16-18 | ≤0.6 | ≤1 | ≤0.75 | ≤0.04 | ≤0.04 | Bal. | |||||||||

| 630 | ≤0.07 | 15.5-17.5 | 6.5-7.5 | ≤1 | ≤1 | 0.15-0.45 | 3-5 | ≤0.035 | ≤0.03 | Bal. | |||||||

| 17-4PH | ≤0.07 | 15.5-17.5 | 3-5 | ≤1 | ≤1 | 0.15-0.45 | 3-5 | ≤0.035 | ≤0.03 | Bal. | |||||||

| 15-5PH | ≤0.07 | 14-15.5 | ≤1 | ≤1 | 0.15-0.45 | 2.5-4.5 | ≤0.04 | ≤0.05 | 3.5-5.5 | ≤0.03 | Bal. | ||||||

| 2Cr13 | 0.16-0.25 | 12-14 | ≤1 | ≤1 | ≤0.035 | ≤0.05 | ≤0.6 | ≤0.03 | Bal. | ||||||||

| SCM415 | 0.13-0.18 | 0.9-1.2 | 0.6-0.85 | 0.15-0.3 | 0.15-0.35 | ≤0.04 | ≤0.03 | Bal. | |||||||||

| S301 | ≤0.15 | 16-18 | 6-8 | ≤2 | ≤1 | ≤0.045 | ≤0.05 | ≤0.1 | ≤0.03 | Bal. | |||||||

| S310 | ≤0.08 | 24-26 | 19-22 | ≤2 | ≤1.5 | ≤0.045 | ≤0.05 | ≤0.03 | Bal. | ||||||||

| S220 | ≤0.03 | 22-23 | 4.5-6.5 | ≤2 | 3-3.5 | ≤1 | ≤0.03 | ≤0.05 | 0.14-0.2 | ≤0.02 | Bal. | ||||||

| 18Ni300 | ≤0.03 | ≤0.3 | 17-19 | ≤0.1 | 4.5-5.2 | ≤0.1 | 8.5-9.5 | 0.6-0.8 | 0.05-0.15 | ≤0.01 | ≤0.05 | ≤0.01 | Bal. | ||||

| H13 | 0.32-0.45 | 4.75-5.5 | 0.2-0.5 | 1.1-1.75 | 0.8-1.2 | 0.8-1.2 | ≤0.03 | ≤0.05 | ≤0.03 | Bal. | |||||||

| 1.2709 | ≤0.03 | ≤0.25 | 17-19 | ≤0.15 | 4.5-5.2 | ≤0.41 | 8.5-10 | 0.8-1.2 | ≤0.01 | ≤0.05 | ≤0.01 | Bal. | |||||

Self-fusing Iron Base Alloy Powder

Self-fusing Iron base alloys are Iron-Carbon alloys with additions of Chromium, Boron, and Silicon. These are typically used on mechanical parts for resisting wear and weak acid corrosion. Even though their properties are not as good as Nickel, Cobalt base alloys, they are readily available and inexpensive, making them popular.

Products Series

| Grade | Hardness (HRC) | Chemical Composition | Particle (mesh) | Application | ||||||||

| C | Cr | Si | Fe | Mo | Ni | Mn | B | Other | ||||

| Fe1 | 35-40 | 0.15 | 22 | 4.5 | Bal. | 2 | 13 | 1.6 | 100/270 | Valve | ||

| Fe2 | 38-44 | 0.15 | 22 | 4.5 | Bal. | 2 | 10 | 1.8 | 100/270 | Valve seat | ||

| Fe5 | 62-67 | 4.5 | 40 | 1 | Bal. | 0.97 | 1.8 | 100/270 | Drilling pipe joint | |||

| Fe90 | 50-55 | 0.15 | 13.5 | 1.3 | Bal. | 1.6 | 100/270 | Drilling pipe joint | ||||

| Fe6 | 58-60 | 0.8 | 7.5 | 2 | Bal. | 32 | 4 | 100/270 | Fan blades | |||

| Fe45 | 40-46 | 0.6 | 7.5 | 2 | Bal. | 22 | 3 | 100/270 | Paper-making machines | |||

| Fe304 | HB190 | 0.03 | 18 | 0.1 | Bal. | 10 | 0.3 | 100/270 | Paper-making machines | |||

| Fe316L | HB190 | 0.03 | 17 | 0.2 | Bal. | 2.5 | 12 | 0.5 | 100/270、300/500 | Paper-making machines | ||

| Fe410L | HB220 | 0.03 | 12.5 | 0.5 | Bal. | 0.1 | 100/270、 300/500 | Pistons | ||||

| JG-1 | 19 | 0.03 | 17 | 0.8 | Bal. | 0.3 | 1.3 | Pistons | ||||

| JG-2 | 26 | 0.04 | 17 | 0.3 | Bal. | 0.2 | 2.6 | Pistons | ||||

| JG-3 | 46 | 0.12 | 16.5 | 0.8 | Bal. | 0.9 | Pistons | |||||

| JG-4 | 63 | 1 | 4 | 0.3 | Bal. | 5 | 0.3 | Pistons | ||||

| Fe253 | 35 | 1.75 | 28 | 1.3 | Bal. | 4.5 | 16 | 0.8 | 100/270 | Engine valve | ||

| Fe253H | 40 | 2.1 | 28 | 1.2 | Bal. | 5.5 | 11.5 | 1 | 100/270 | Engine valve | ||

| Fe101 | 62 | 3.3 | 2 | 1 | Bal. | 5 | 1 | 1.4 | 20/300 | Extrusion barrels | ||

| Fe102 | 62 | 2.7 | 2.8 | 1 | Bal. | 5.5 | 1 | 1.9 | 20/300 | Extrusion barrels | ||

| Fe103 | 62 | 1.5 | 4.5 | 1 | Bal. | 7 | 1 | 2.9 | W:4.5 | 20/300 | Extrusion barrels | |

| Fe104 | 60 | 1.7 | 4.5 | 1.5 | Bal. | 11 | 0.8 | 3 | 20/300 | Extrusion barrels | ||

| Fe105 | 62 | 1.5 | 4.5 | 1.3 | Bal. | 1.5 | 12 | 1 | 2.8 | 20/300 | Extrusion barrels | |

| Fe106 | 62 | 1.08 | 5.42 | 2.01 | Bal. | 27 | 0.89 | 3.08 | 20/300 | Extrusion barrels | ||

| Fe107 | 62 | 1.36 | 6.25 | 1.56 | Bal. | 16.2 | 1.02 | 2.98 | 20/300 | Extrusion barrels | ||

Spherical Iron Based Alloy Powder Applicable Processes

High strength, high hardness, good high-temperature performance, excellent wear resistance, and corrosion resistance

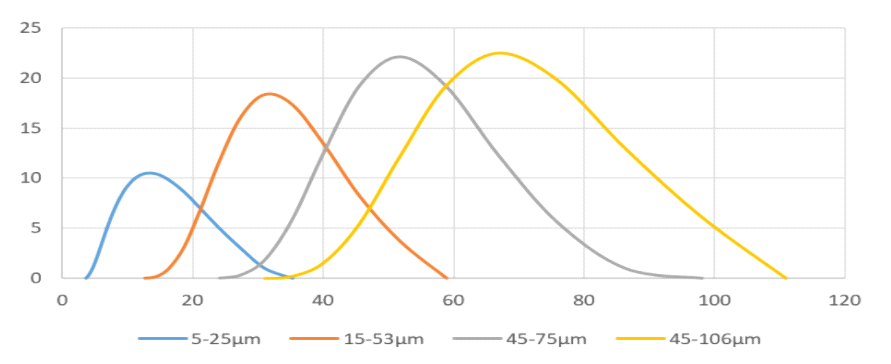

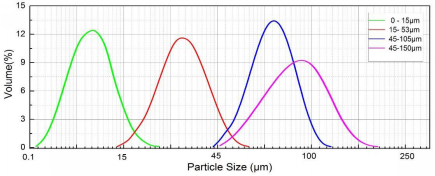

Spherical Iron Based Alloy Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Spherical Iron Based Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Iron Based Alloy Powder Application

Iron-based alloy powder can be used on the working layer of abrasion-resistant anticorrosive parts, such as hydraulic turbine blade, nozzle, wearing ring, hydraulic rod. The stainless steel powder has a good sphericity configuration with low oxygen content, high hardness, and good toughness.

Packing of Spherical Iron Based Alloy Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Iron Based Alloy Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.