Product Code : 3D-Mo-CU-PO1

Spherical molybdenum powder is widely used in plasma surface spray welding of high-speed wear-resistant parts of aerospace and automobile engines, precision molding of electronic components, high-performance targets and 3D. It is a large class of special molybdenum powder products with high added value and high technical content prepared from powder metallurgy molybdenum powder.

We provide spherical molybdenum powder with the characteristics of high purity, low oxygen, high sphericity, smooth surface, no satellite sphere, few hollow particles, and uniform particle size distribution. With its excellent flow performance as well as high loose loading density and vibrational density, spherical molybdenum powder is widely used in contact materials, aerospace high-temperature resistant components, target materials, and other fields, and it is also suitable for laser/electron beam augmentation (3 D printing), laser direct deposition, thermal isostatic pressing, injection molding, laser cladding, and other processes.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Synonyms

Mo spherical particles, molybdenum spherical particles, molybdenum spherical powder, molybdenum metal spherical powder

Spherical Molybdenum (Mo) Powder Characteristics

High purity (99.9% min.)

Low oxygen (can be less than 200 ppm)

High sphericity (98% min.)

Smooth surface, no satellite

Uniform particle size distribution, excellent flowability (Hall Flow Rate ≤ 12.0 s/50 g)

High bulk density (≥ 6 g/cm3) and tap density (≥ 6.5 g/cm3)

Spherical Molybdenum Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 45-150μm, 75-150μm.

(Various granularities can be customized according to customer requirements)

Spherical Molybdenum Powder Applicable processes

Laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

Direct laser deposition (DLD)

Powder hot isostatic pressing (HIP)

Metal injection molding (MIM)

Powder metallurgy (PM)

Laser cladding (LC), etc.

Spherical Molybdenum Powder Chemical Composition

| Chemical Composition: | Wt % |

| Mo | ≥ 99.9 |

| Al | <0.002 |

| Ni | <0.001 |

| Mg | <0.002 |

| Si | <0.005 |

| Fe | <0.005 |

| Ca | <0.002 |

| Cu | <0.005 |

| Gas Impurities | |

| O | ≤0.02 |

| N | ≤0.003 |

| C | ≤0.005 |

Spherical Molybdenum Powder Physical Properties

| Form: | Powder |

| Color: | Black |

| Melting Point: | 2617°C |

| Boiling Point: | 4612°C |

| Density: | 10.2 g/cm3 |

| Density (g/cm3) | Hall Flow Rate (s/50g) | ||||

| Apparent Density | Tap Density | Value | |||

| >6.0 | >6.5 | </= 12.0 | |||

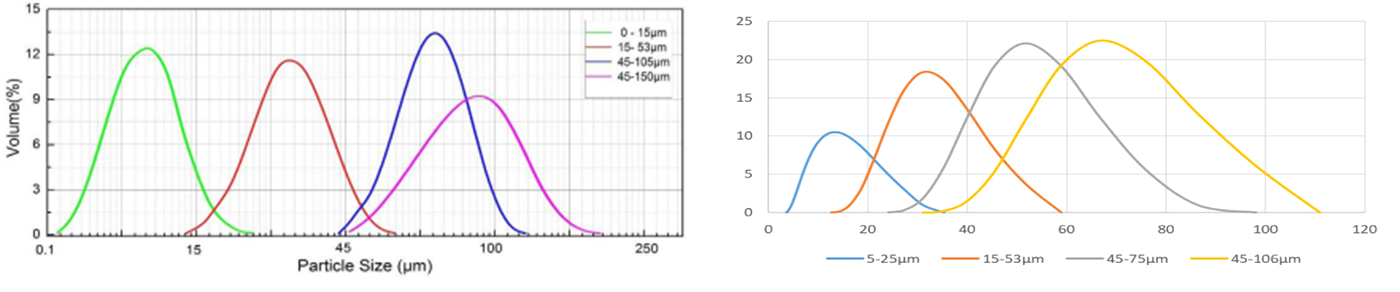

Spherical Molybdenum Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Molybdenum Powder Packaging

Standard Packing: Vacuum packaging, 1 kg/bag or 2 kg/bag. Iron drums lined with a plastic bag, 25 kg/drum. Special package is available on request.

Chemical Identifiers

| Linear Formula | Mo |

| MDL Number | MFCD00003465 |

| CAS | 7439-98-7 |

| EC No. | 231-107-2 |

| Beilstein/Reaxys No. | N/A |

| Pubchem CID | 23932 |

| SMILES | [Mo] |

| InchI Identifier | InChI=1S/Mo |

| InchI Key | ZOKXTWBITQBERF-UHFFFAOYSA-N |