Product Code : 3D-CoCrMo-CU-PO1

The Spherical Cobalt-based powder is a metal material with high-temperature resistance, high strength, high corrosion resistance, and good elasticity. It is widely used in fine parts and can also be used to produce bone implants and artificial teeth, etc.

Spherical Cobalt-based alloys Powders are widely used in the medical field because of their excellent corrosion resistance, mechanical properties, and biological properties. Our powder has the characteristics of high sphericity, good fluidity, high purity, large loose density, full density inside particles, no hollow powder.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Spherical Cobalt-based Powder for 3D Printing Specifications

| Form | spherical |

| Flowability | ≤18s |

| Apparent density | ≥4.2g/cc |

| Oxygen content | ≤200ppm |

| Nitrogen content | ≤100ppm |

| Composition(%) | Cr:26.5-29; Fe≤0.6; W:7.0-9.0; Mn≤0.4; Si:1.2-1.9; Co:Bal |

| Tensile strength(Mpa) | 330±50 |

| Yield strength(Mpa) | 220±30 |

| Ductility (%) | 5±1 |

Spherical Powder-Cobalt Based Alloys Chemical Composition

| Element | Min | Max | Unit |

| Cr | 27.0 | 30.00 | % |

| Mo | 5.0 | 7.00 | % |

| Al | 0.10 | % | |

| B | 0.01 | % | |

| C | 0.02 | % | |

| Fe | 0.75 | % | |

| Mn | 1.00 | % | |

| N | 0.25 | % | |

| Ni | 0.10 | % | |

| O | 0.05 | % | |

| P | 0.02 | % | |

| S | 0.01 | % | |

| Si | 1.00 | % | |

| Ti | 0.10 | % | |

| W | 0.20 | % | |

| Co | balance |

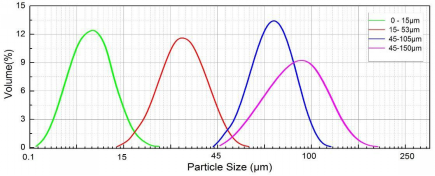

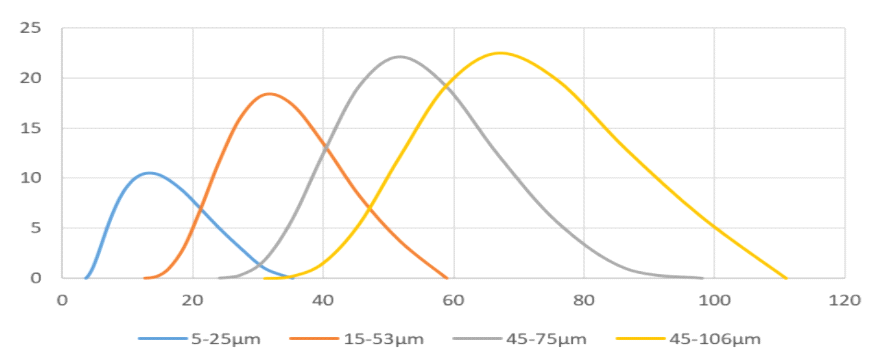

Spherical Powder-Cobalt Based Alloys Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Powder-Cobalt Based Alloys Characteristics

Cobalt-based alloy is a kind of hard alloy that can resist various types of wear and corrosion as well as high-temperature oxidation. It is commonly known as cobalt-chrome-tungsten (molybdenum) or Stellite( an alloy invented by Elwood Haynes in 1907). Cobalt-based alloys are alloys in which cobalt is the principal component and contains significant amounts of nickel, chromium, tungsten, and small amounts of molybdenum, niobium, tantalum, titanium, lanthanum, and occasionally iron. Depending on the composition of the alloy, they can be made into welding wire, powder for hard surfacing, thermal spraying, spray welding, and other processes, as well as cast and forged parts and powder metallurgy parts.

Spherical Powder-Cobalt Based Alloys Applicable Processes

According to its application, cobalt base alloy can be divided into the cobalt-base wear-resistant alloy, cobalt-base high-temperature resistant alloy, cobalt-base wear resistance, and aqueous solution corrosion alloy. General working conditions, in fact, are both wear resistance and high-temperature resistance or wear resistance and corrosion resistance, some working conditions may also require high-temperature resistance and wear resistance and corrosion resistance, and the more complex working conditions, the more can reflect the advantages of cobalt-based alloy.

Spherical Powder-Cobalt Based Alloys Application

General cobalt-based superalloys lack a uniform strengthening phase. Although the strength at medium temperature is low (only 50-75% of that of nickel-based alloys), they have high strength, good thermal fatigue resistance, thermal corrosion resistance, and abrasion resistance at higher than 980℃, and good weldability. It is suitable for the production of guide vane and nozzle guide vane of aviation jet engine, industrial gas turbine, naval gas turbine, diesel nozzle, etc.

Packing of Spherical Powder-Cobalt Based Alloys

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Powder-Cobalt Based Alloys is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.