Product Code : 3D-CrMnFeCoNi-CU-PO1

High-entropy alloys are a new type of metal material composed of 4, 5, or more metal elements in nearly equal atomic ratios, also known as complex component alloys. As CrMnFeCoNi, which have high strength, high hardness, good high-temperature performance, excellent wear resistance, and corrosion resistance.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Product Information

High-entropy alloys are a new type of metal material composed of 4, 5, or more metal elements in nearly equal atomic ratios, also known as complex component alloys. As CrMnFeCoNi, which have high strength, high hardness, good high-temperature performance, excellent wear resistance, and corrosion resistance.

A series of refractory high entropy alloys, such as CrMnFeCoNi, have high strength, high hardness, good high-temperature performance, excellent wear resistance, and corrosion resistance. RF plasma spheroidized refractory high son-in-law alloy powder has the characteristics of high purity, good sphericity, no satellite ball, excellent fluidity, and few hollow particles and it is suitable for 3D printing, hot isostatic pressing, injection molding, laser cladding, and so on.

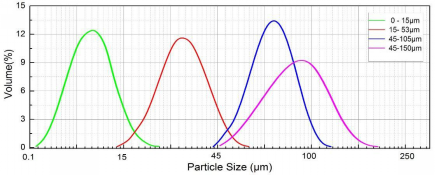

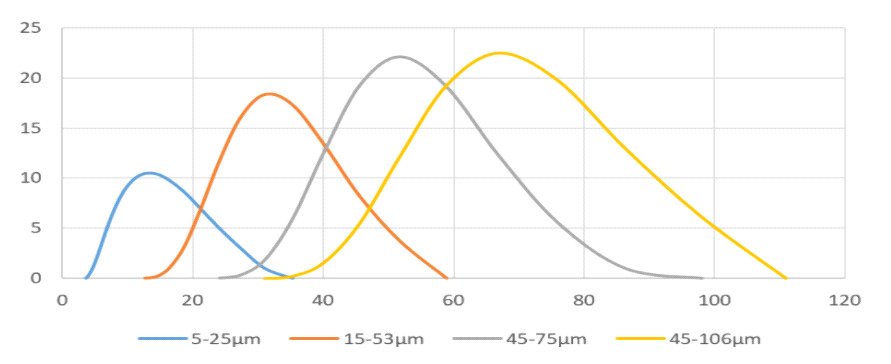

Spherical Refractory HEA Powder (Cr-Mn-Fe-Co-Ni) Particle Size

0-15μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements).

Spherical Refractory HEA Powder (Cr-Mn-Fe-Co-Ni) Applicable processes

High strength, high hardness, good high-temperature performance, excellent wear resistance, and corrosion resistance

Spherical Refractory HEA Powder (Cr-Mn-Fe-Co-Ni) Application

Spherical HEAs powder have gained interest for their promising properties including enhanced irradiation resistance, high-temperature strength, and corrosion resistance

Spherical Refractory High-entropy Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Packing of Spherical Refractory High-entropy Alloy Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Refractory High-entropy Alloy Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.