Product Code : 3D-TiGrade23-CU-PO1

Titanium Grade 23 is similar to Grade 5 but has lower oxygen, nitrogen, and iron.

The nominal chemical composition of TC4 alloy is Ti-6Al-4V, which has excellent mechanical properties, biocompatibility, and corrosion resistance, and has been widely used in aerospace, medical, chemical, and other fields.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Spherical Titanium Powder Grade 23 Synonyms

Titanium 6AL-4V, Titanium Ti 6AL 4V, Grade 5, Ti-6Al-4V, Ti 6-4, Ti6Al4V, TiAlV alloy, 99906-66-8, 12743-70-3, Ti64, Ti 6Al 4V alloy (O), Oxygen in titanium-aluminium-vanadium alloy, Titanium-aluminum-vanadium alloy Ti with 6% Al and 4% V

Spherical Titanium Powder Grade 23 Chemical Composition

| Grade | Al | V | Fe | C | N | H | O |

| TC4 | 5.5~6.75 | 3.5~4.5 | ≤0.30 | ≤0.08 | ≤0.05 | ≤0.015 | 0.08~0.15 |

| TC4ELI | 5.5~6.5 | 3.5~4.5 | ≤0.25 | ≤0.08 | ≤0.03 | ≤0.012 | 0.08~0.13 |

| Element, Mass Fraction(Wt.%) | |||||||

Spherical Titanium Powder Grade 23 Size and Properties

The regular powder size is as follows: 0~20μm, 15~45μm, 15~53μm, 20~63μm and 75~180μm, custom size powders are also available. The particle size was measured by the laser diffraction method.

| Particle Size | Granularity Eigenvalue(μm) | Powder Performance | Applicable Process | ||||

| D(10) | D(50) | D(90) | Hall Velocity | Apparent Density | Tap Density | ||

| 0~20μm | ≥5 | 12~18 | ≤25 | - | - | - | PM |

| 15~45μm | ≥15 | 25~35 | 45~55 | ≤40s/50g | - | ≥2.7/cm³ | SLM |

| 15~53μm | ≥18 | 32~42 | 55~63 | ≤40s/50g | 2.2g/cm³ | ≥2.7/cm³ | SLM |

| 20~63μm | ≥20 | 40~50 | 63~70 | ≤40s/50g | 2.2g/cm³ | ≥2.7/cm³ | SLM |

| 75~180μm | ≥70 | 110~130 | 170~190 | ≤30s/50g | 2.2g/cm³ | ≥2.7/cm³ | LMD |

Properties(Theoretical)

| Compound Formula | TiAlV |

| Appearance | Silvery-gray powder |

| Melting Point | 1604-1660 °C |

| Boiling Point | N/A |

| Density | 4.43 g/cm3 |

| Solubility in H2O | Insoluble |

| Electrical Resistivity | 0.000178 ohm-cm |

| Specific Heat | 0.5263 J/g-°C |

| Tensile Strength | 950-1000 MPa |

| Thermal Conductivity | 6.7 W/m-K |

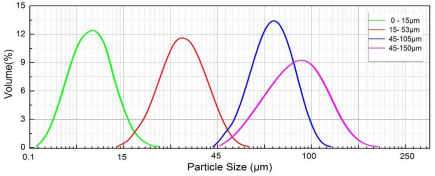

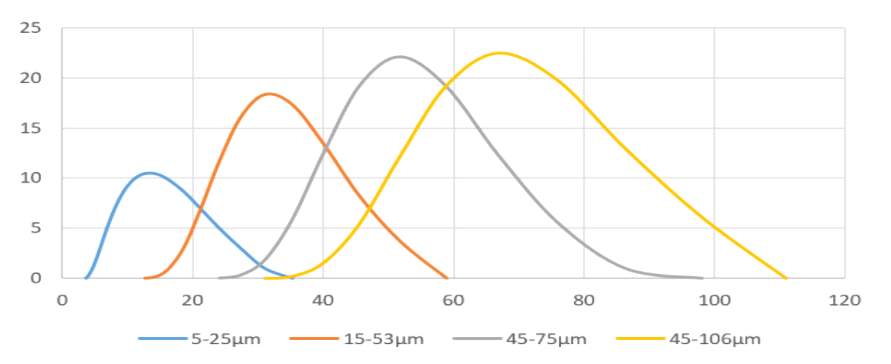

Spherical Titanium Powder Grade 23 Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Titanium Powder Grade 23 Applicable Process

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM), powder metallurgy (PM), laser cladding (LC), and other processes.

Packing of Spherical Titanium Powder Grade 23

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Titanium Powder Grade 23 is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.