Product Code : 3D-TZM-CU-PO

TZM alloy, molybdenum zirconium titanium alloy, titanium zirconium molybdenum alloy. It is a kind of superalloy commonly used in molybdenum-based alloy, which is composed of 0.50% titanium, 0.08% zirconium, and the remaining 0.02% carbon molybdenum alloy. TZM alloy has the characteristics of high melting point, high strength, high elastic modulus, low linear expansion coefficient, low vapor pressure, good conductivity and thermal conductivity, strong corrosion resistance and good high temperature mechanical properties, so it is widely used in many fields.

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) is available as bars, sheets, plates, blocks, tubes, discs, and in numerous other forms, or customized according to the drawing. TZM Products offer twice the strength of pure molybdenum products at temperatures over 1300℃. The recrystallization temperature of TZM is approximately 250°C higher than moly and it offers better weldability.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

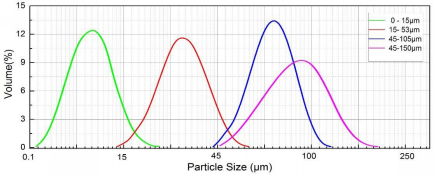

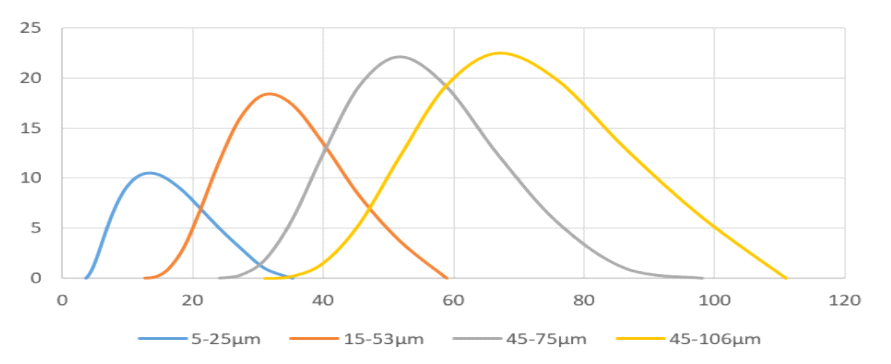

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Specifications

| Elements | Content % |

| Mo | 99.2-99.5 |

| Ti | 0.40-0.55 |

| Zr | 0.06-0.12 |

| C | 0.01-0.04 |

| Fe | ≤0.010 |

| Ni | ≤0.005 |

| Si | ≤0.010 |

| N | ≤0.003 |

| O | ≤0.080 |

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Characteristics

TZM alloy has the characteristics of high melting point, high strength, high elastic modulus, low linear expansion coefficient, low vapor pressure, good conductivity and thermal conductivity, strong corrosion resistance and good high temperature mechanical properties, so it is widely used in many fields.

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Applicable Processes

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder thermal and other static pressure forming (HIP), metal injection forming (MIM), powder metallurgy (PM), laser melting application (LC), etc.

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) Applications

Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) is mainly used in applications of mold materials for thermal processing, structural materials for high temperature, and high-pressure equipment, such as heat shields, pillars, etc. It is also used in high-temperature sintering dishes, hot gas sealing of gas valves, and high-temperature gas systems.

Packing of Spherical Titanium Zirconium Molybdenum Powder (TZM Powder)

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Titanium Zirconium Molybdenum Powder (TZM Powder) is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.