Product Code : 3D-WRe-CU-PO5

Spherical Tungsten-Rhenium Alloy Powder has the characteristics of high melting point, high recrystallization temperature, and high thermal potential. It also features high resistivity, corrosion resistance, good plasticity, excellent creep resistance at high temperatures, weldable and machined. The proper amount of rhenium can be dissolved in tungsten to form a solid solution alloy powder.

Tungsten rhenium alloy is the most ideal structural material and thermocouple material in the field of high temperature technology. The application of tungsten rhenium alloy spherical powder additive in the nuclear industry, aviation and military industry and other cutting-edge fields is expected to achieve greater breakthroughs.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Tungsten Rhenium Alloy Synonyms

75W25Re, 75W-25Re, W-25, W97Re3, ASM W-10

Spherical Tungsten-Rhenium Alloy Powder Applicable processes

-Laser/electron beam additive manufacturing (SLM/EBM)

-Injection molding (MIM)

-Hot isostatic pressing (HIP)

-Powder metallurgy (PM)

-Spraying (SP) and other processes.

Spherical Tungsten-Rhenium Alloy Powder Characteristics

High purity, ultra-low oxygen (≤500ppm), high sphericity (≥98%), smooth surface, no satellite ball, uniform particle size distribution.

Spherical Tungsten-Rhenium Alloy Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 53-105μm, 53-150μm, 105-250μm, Customized.

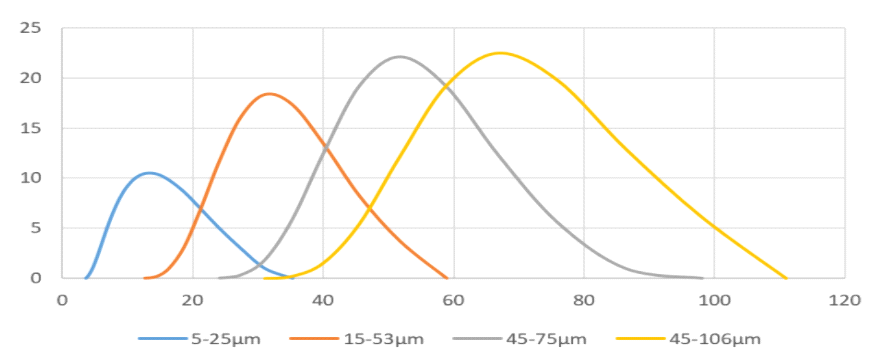

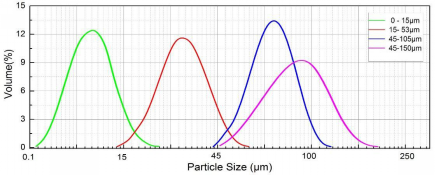

Spherical Tungsten-Rhenium Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Tungsten-Rhenium Alloy Powder Applications

- Tungsten-rhenium alloys are mainly used as structural materials in high-temperature fields and are widely used in electronic technology, nuclear technology, aerospace technology, and temperature measurement technology.

- High-end, high-quality, high-performance tungsten-based materials

- Deformed processed products, such as plates, sheets, wires, wires, and rods

- They can replace pure tungsten, lanthanum tungsten, cerium tungsten, doped tungsten, and other tungsten materials. They have higher strength, service life, and high-temperature performance stability than pure tungsten, with higher cost performance.

- High-temperature structural parts in extreme service environments (nozzles, nozzles, heat shields, etc.)

- Special filaments, electrodes, electronic components, etc.

Packing of Spherical Tungsten-Rhenium Alloy Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’Spherical Tungsten-Rhenium Alloy Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Chemical Identifiers

| Linear Formula | WRe |

| CAS | 12299-18-2 |

| MDL Number | MFCD02091751 |

| EC No. | N/A |

| Beilstein/Reaxys No. | N/A |

| Pubchem CID | 25252736 |

| IUPAC Name | rhenium; tungsten |

| SMILES | [W].[Re] |

| InchI Identifier | InChI=1S/Re.W |

| InchI Key | DECCZIUVGMLHKQ-UHFFFAOYSA-N |