Product Code : 3D-17-4PH-CU-PO1

17-4PH is stainless steel with high yield strength, high wear resistance as well as good corrosion resistance. It is possible to be used in low temperatures and has excellent impact strength even at minus temperatures. Due to the combination of corrosion resistance and good mechanical properties, this material 17-4PH is also suitable for use in maritime environments, whenever the corrosion resistance and mechanical properties of martensitic steels are insufficient. Standing seawater is vulnerable to corrosion fissures. 17-4PH is used in plant construction, chemical industry, wood industry, offshore, shipbuilding, mechanical engineering, oil industry, paper industry, air, and water industry. space travel, sports, and leisure industry.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Stainless Steel 17-4PH Spherical Powder Synonyms

AMPERSINT 0711.01, FeCrNiCuNb, 17-4PH precipitation hardening steel, FE-206-2, FE-206-3

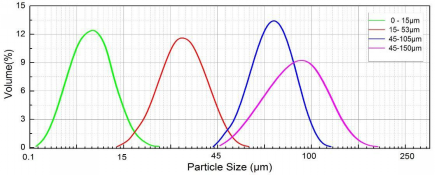

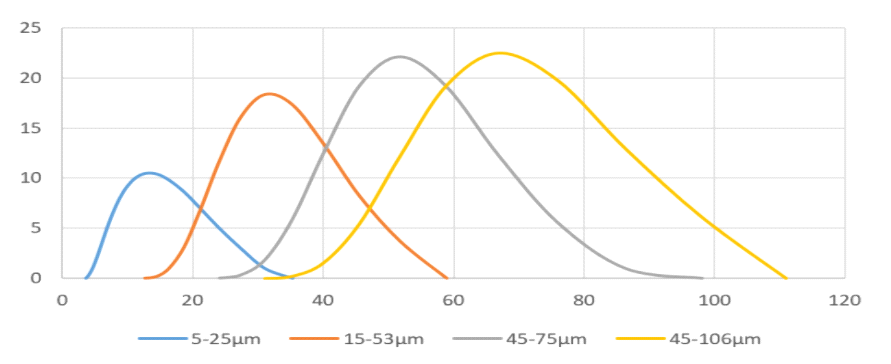

Stainless Steel 17-4PH Spherical Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. (Various granularities can be customized according to customer requirements)

Characteristics of Stainless Steel 17-4PH Spherical Powder

- Low pick-up of oxygen and other impurities

- Perfectly spherical and essentially satellite-free

- Narrow particle size distribution.

- High flowability and high packing density

- Low internal porosit

Stainless Steel 17-4PH Spherical Powder Characteristics

Chemical Composition [ wt.% ]

Element Min Max

Cr 15.0 17.0

Ni 3.0 5.0

Cu 3.0 5.0

Nb 5xC 0.45

Fe Balance Balance

Stainless Steel 17-4PH Spherical Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Stainless Steel 17-4PH Spherical Powder Applicable Process

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM), powder metallurgy (PM), laser cladding (LC), and other processes.

Stainless Steel 17-4PH Spherical Powder Application:

Offshore platforms

helidecks

other platforms

Food industry

Pulp and paper industry

Packing of Stainless Steel 17-4PH Spherical Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’ Stainless Steel 17-4PH Spherical Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.