Product Code : 3D-WMo-CU-PO1

Spherical tungsten molybdenum (W-Mo) alloy powder is an alloy powder with two refractory metal elements, tungsten, and molybdenum, as the main raw materials. It is also called molybdenum-tungsten alloy powder because the molybdenum content is usually greater than the tungsten content (30wt% to 50wt%).

Our W-Mo alloy powders have uniform composition, concentrated particle size distribution (15‑53μm), high sphericity, and low oxygen content (O≤ 300 ppm). It can meet the requirements of the 3D printing (additive manufacturing) process.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Tungsten Molybdenum Alloy Spherical Powder Synonyms

MoW, Molybdenum, compd. with tungsten

Chemical Composition

| Element | Value % | Element | Value % |

| W | 2~98 | Sn | <0.001 |

| Mo | 2~98 | Sb | <0.001 |

| Si | 1.0~9.0 | Cu | <0.003 |

| Mg | <0.005 | Ca | <0.001 |

| Mn | <0.004 | Pt | <0.001 |

| Ni | <0.006 | K+Na | <0.001 |

Tungsten Molybdenum Alloy Spherical Powder characteristics:

Adjustable and controllable content of tungsten and molybdenum, high purity (≥99.9%), low oxygen (≤300ppm), high sphericity (≥98%), smooth surface, no satellite spheres, uniform particle size distribution, excellent Flowability (≤10.0s/50g) and high bulk density (≥6.0g/cm3) and tap density (≥7.0g/cm3).

Specifications and properties of Spherical Tungsten Molybdenum Alloy Powder:

| Appearance | Silver gray powder of flakes |

| Assay Percent Range | 99.8% (Metals basis) |

| Mesh Size | As request |

| Odor | Odorless |

| Physical Form | Spherical Powder |

| Color | Silver to Gray |

| Chemical Name or Material | Tungsten Molybdenum |

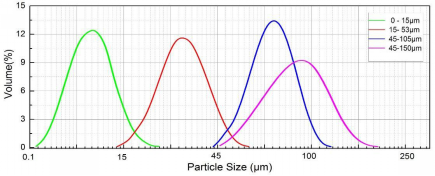

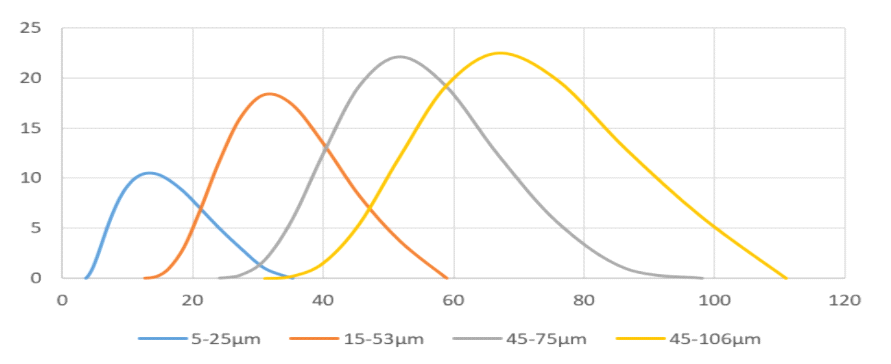

Spherical Tungsten Molybdenum Alloy Powder Particle Size Description

● 0-15μm (D10=3~5μm, D50=6~10μm, D90=12~14μm)

● 5-25μm (D10=5~10μm, D50=15~20μm, D90=20~25μm)

● 15-45μm (D10=15~20μm, D50=25~30μm, D90=35~40μm)

● 15-53μm (D10=15~20μm, D50=25~35μm, D90=45~50μm)

● 45-75μm (D10=45~55μm, D50=55~65μm, D90=70~75μm)

● 45-105μm (D10=50~60μm, D50=75~85μm, D90=95~105μm)

● 45-150μm (D10=55~70μm, D50=110~120μm, D90=140~150μm)

● 75-150μm (D10=80~90μm, D50=110~125μm, D90=135~150μm)

Tungsten Molybdenum Alloy Spherical Powder Particle Size

0-15μm, 5-25μm, 15-45μm, 15-53μm, 45-75μm, 45-105μm, 75-150μm. Various granularity can be customized according to customer requirements.

Spherical Tungsten Molybdenum Alloy Powder Applicable Process

Laser/electron beam additive manufacturing (SLM/EBM), laser direct deposition (DLD), powder hot isostatic pressing (HIP), metal injection molding (MIM), powder metallurgy (PM), laser cladding (LC), and other processes.

Tungsten Molybdenum Alloy Spherical Powder Application

Spherical tungsten-molybdenum alloy powder can be used to produce filaments for light bulbs, heating elements for high-temperature electric furnaces, grids for electron tubes, corrosion-resistant parts for zinc smelting furnaces, flow port and ejector parts for Boucher furnaces, and parts such as gas rudders and shields for rocket engines.

Packing of Tungsten Molybdenum Alloy Spherical Powder

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’ Tungsten Molybdenum Alloy Spherical Powder is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

Chemical Identifiers

| Linear Formula | MoW |

| CAS | 870196-77-3 |

| Pubchem CID | 57450966 |

| IUPAC Name | molybdenum; tungsten |

| SMILES | [Mo].[W] |

| InchI Identifier | InChI=1S/Mo.W |

| InchI Key | MGRWKWACZDFZJT-UHFFFAOYSA-N |