Product Code : AL-CuAINi-NN-CU

SCSMA is a remarkable material manufactured by EBAD from Copper, Aluminum, and Nickel (Cu-Al-Ni). This alloy exhibits significantly enhanced performance over commercially available SMAs. These include:Significantly greater strain recovery (9% vs. 3%),Much higher transition temperature capability (250°C vs.100°C),True constant force deflection,Very narrow loading hysteresis,Recovery which is 100% repeatable and complete。SCSMAs are manufactured by “growing” as a single crystal from a melt, by a similar method as that used by the semiconductor industry to fabricate silicon boules. The “grown” material is generally fabricated as a rod but can have a range of cross sections (i.e., solid, hollow, flat, or oval). The material can also be subsequently formed into other shapes by traditional fabrication methods such as grinding, machining, or EDM (Electro-Discharge-Machining). A shape memory alloy (SMA) is a metal alloy that demonstrates pseudo-elasticity and the shape memory effect. The shape memory effect is when a material returns to its pre-deformed shape by heating. These unusual properties are being applied to a wide assortment of applications in a number of different fields including the medical and aerospace fields.

Please contact us if you need customized services. We will contact you with the price and availability in 24 hours.

| Product | Product Code | Purity | Size | Contact Us |

Product Information

SCSMA is a remarkable material manufactured by EBAD from Copper, Aluminum, and Nickel (Cu-Al-Ni). This alloy exhibits significantly enhanced performance over commercially available SMAs. These include:Significantly greater strain recovery (9% vs. 3%),Much higher transition temperature capability (250°C vs.100°C),True constant force deflection,Very narrow loading hysteresis,Recovery which is 100% repeatable and complete。SCSMAs are manufactured by “growing” as a single crystal from a melt, by a similar method as that used by the semiconductor industry to fabricate silicon boules. The “grown” material is generally fabricated as a rod but can have a range of cross sections (i.e., solid, hollow, flat, or oval). The material can also be subsequently formed into other shapes by traditional fabrication methods such as grinding, machining, or EDM (Electro-Discharge-Machining). A shape memory alloy (SMA) is a metal alloy that demonstrates pseudo-elasticity and the shape memory effect. The shape memory effect is when a material returns to its pre-deformed shape by heating. These unusual properties are being applied to a wide assortment of applications in a number of different fields including the medical and aerospace fields.

Synonyms

SMA, Cu13Al14Ni, Cupro Aluminium Nickel, CuAlNi, Cu-Al-Ni, AlCuNi, Al-Cu-Ni, copper-aluminium-nickel, aluminium-copper-nickel, aluminium-nickel-copper, AnNiCu, Al-Ni-Cu, NiCuAl, Ni-Cu-Al

CuAINi ALLOY Specification

Size:customized

Purity: customized

Per your request or drawing

We can customized as required

Properties(Theoretical)

| Density | 7.1g/cm3 |

| Specific Heat (Cp) | 0.5 J/g/°C |

| Latent Heat (Lt) | 8.3J/g |

| Thermal Conductivity | 30-43W/m*0℃ |

| Young's Modulus (Austenite) | 30 GPa |

| Yield Strength (Austenite) | 950MPa |

| Ultimate Strength (Austenite) | 1000MPa(min) |

| Elastic Strain Limit | 0.09 |

| Life Cycle | 1 M+ Cycles |

| Plateau Stress (min) | 100 Mpa |

| Plateau Stress(max) | 800 Mpa |

| Recommended Stress (max) 600 | 600 Mpa |

| Loading Unloading Hysteresis | 35 Mpa |

| Thermal Hysteresis | <25 °C |

| Approximate Composition: | |

| Copper (Cu) | 80 Wt%,customized |

| Aluminum (Al) | 15 Wt%,customized |

| Nickel (Ni) | 5 Wt%,customized |

| Group | No. | Alloy composition | Transformation temperature (°C) | Hysteresis (°C) | Tensile strain (%) | Strain recovery (%) | Remarks/features |

| Cu-based shape memory alloys | 1 | Cu-Al-Ni | 100–400 | 21.5 | 3–5 | 60–90 | Low cost |

| Reasonable shape memory | |||||||

| Good pseudoelastic behavior | |||||||

| Brittle in tension | |||||||

| Stable phase precipitation near 200°C | |||||||

| Reordering causes shift in transformation temperature in quenched specimen | |||||||

| 2 | Cu-Zn-Al | 120 | 15–25 | 4 | 70–85 | High thermal conductivity | |

| Reasonable recoverable shape memory strain | |||||||

| Inexpensive | |||||||

| Brittle alloys | |||||||

| 3 | Cu-Al-Be | 150–200 | 20–25 | 3–5 | 80–90 | Reasonable recoverable shape memory strain | |

| High transformation temperatures | |||||||

| High corrosion resistance | |||||||

| 4 | Cu-Al-Ni-Mn | 230–280 | 15–20 | 3–4 | 90–100 | High shape memory behavior | |

| Reasonable materials cost | |||||||

| High transformation temperatures | |||||||

| Good corrosion resistance | |||||||

| 5 | Cu-Al-Ni-Ti | 120–260 | 12–20 | 2.5–4 | 90–100 | High shape memory behavior | |

| Reasonable materials cost | |||||||

| High transformation temperatures | |||||||

| High corrosion resistance | |||||||

| 6 | Cu-Al-Ni-Fe | 210–250 | 12–15 | 9 | 40 | Low shape memory behavior | |

| High ductile material | |||||||

| Reasonable materials cost | |||||||

| High transformation temperatures | |||||||

| High corrosion resistance |

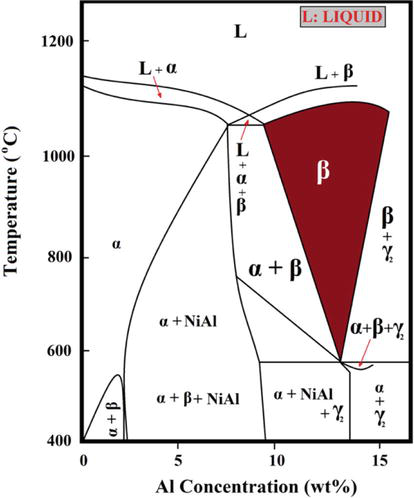

Phase diagram of Cu-Al-Ni SMAs

Applications of CuAINi ALLOY

there are several basic types of SMAs, such as Ni-Ti (nitinol), Cu-based, and Fe-based alloys , All of the above types have advantages and disadvantages, while economical aspects such as the price can be very important for material selection and application. Precisely, the economic effect (low price) is the main advantage of Cu-based SMAs compared with other SMAs. Namely, these alloys (Cu-Al-Ni alloys) can be applied in various industrial fields, especially when high transformation temperatures are required (near 200 °C), thanks to their high thermal stability and high transformation temperatures. The selection for application of this group of alloys is affected by their characteristics such as high transformation temperatures (high thermal stability at elevated temperatures, above 200 °C); high corrosion resistance; high resistance to degradation of functional properties during aging processes; and, last but not least, the reasonable cost. Some of the usual applications include the different types of engineering sectors, such as automotive, aerospace, medical and biomedical, and construction。

Packing of CuAINi ALLOY

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber and steel drums to 1 ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing or other air sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic or glass jars up to palletized 440 gallon liquid totes Special package is available on request.

ATTs’ CuAINi ALLOY is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.