Molybdenum is well-known for its strength and stability in high-heat applications. It is often alloyed with other compounds to improve corrosion resistance and strength at high temperatures. Consequently, molybdenum is frequently used for making steel alloys, high-strength alloys, and superalloys. Molybdenum compounds usually have a low solubility in water. Industrially, they are used in high-pressure and high-temperature applications such as pigments and catalysts.

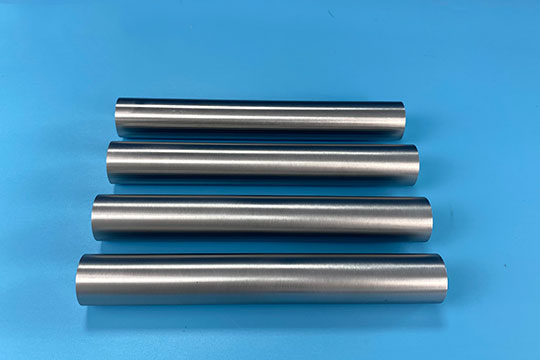

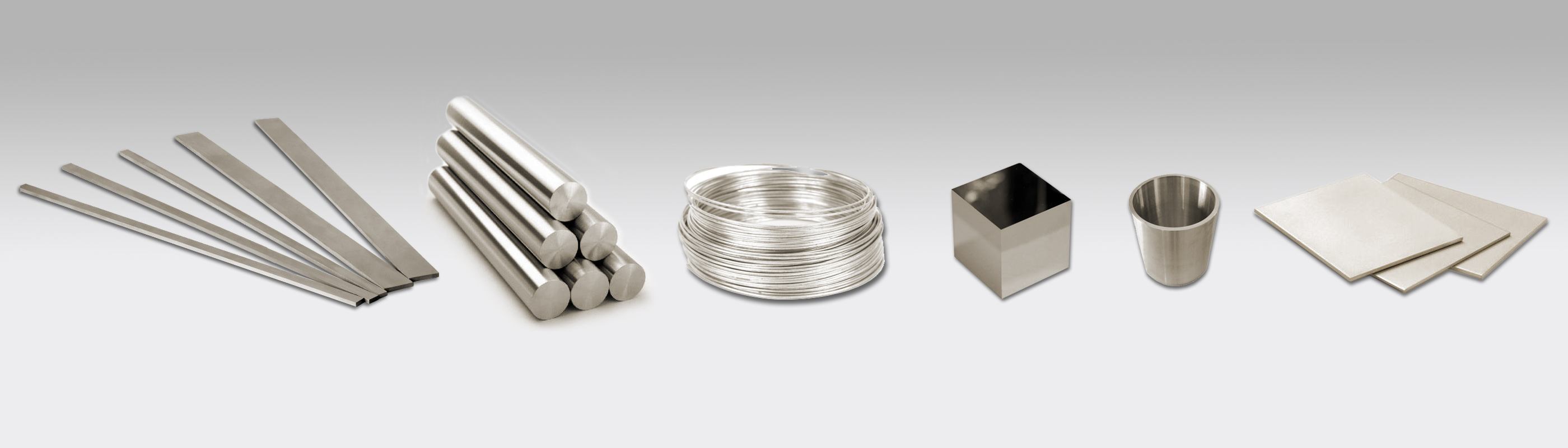

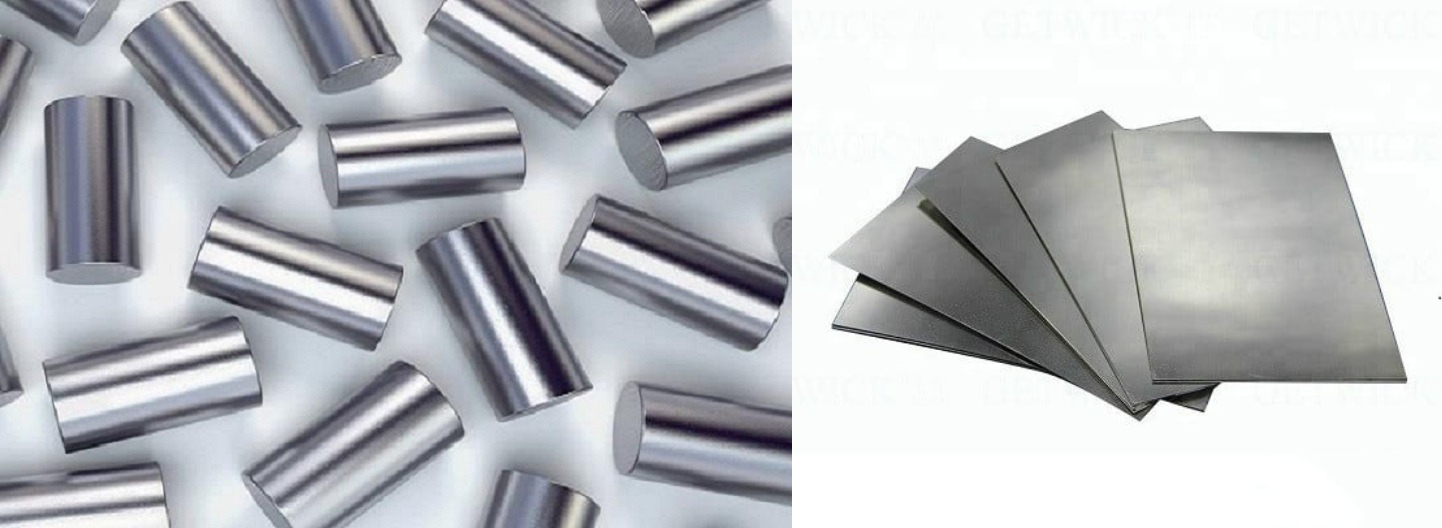

Molybdenum Lanthanum alloy (Mo-La alloy) is one of the Moly-REO alloys (Molybdenum-rare earth oxide), it is also called rare earth molybdenum or La2O3 doped molybdenum. Molybdenum Lanthanum alloy (Mo-La alloy) is an oxide dispersion-strengthened alloy. Mo-La alloy is a useful and important molybdenum alloy composed by adding lanthanum oxide to molybdenum. It has the properties of higher temperature of recrystallization, better ductility, and excellent wear resistance. The recrystallizing temperature of Mo-La alloy is higher than 1,500 degrees Celsius. It can be used in illumination, electric vacuum devices, tube component elements in cathode-ray pipes, power semiconductor devices, tools for manufacturing glass and glass fiber, internal parts in light bulbs, high-temperature heat shields, annealing Filament and Electrode, high-temperature container and component in microwave magnetron. Mo-La alloy sheet, plate, rod, bar, foil, and wire, machined parts for high-temperature furnaces are available.

Molybdenum-lanthana (MoLa) alloys are one type of ODS molybdenum-containing molybdenum and a very fine array of lanthanum trioxide particles. Small quantities of lanthanum oxide particles (0.3 or 0.7 percent) give the molybdenum a so-called stacked fiber structure. This special microstructure is stable at up to 2000°C.

- 0.3 wt. % Lanthana > Considered a substitute for pure molybdenum but with longer life due to its increased creep resistance

- 0.6 wt. % Lanthana > Standard level of doping for the furnace industry, most popular

- 1.1 wt. % Lanthana > Strong warpage-resistance

- Medical devices

- Aircraft and Aerospace components

- Nuclear Fuel Pellet production

- High Pulse Magnet Research

Molybdenum lanthanum alloy is an ideal material for applications requiring dimensional stability and strength at temperatures above the capabilities of either pure Molybdenum or TZM alloy. Molybdenum-lanthanum alloy is often used in illumination, electric vacuum devices, tube components in the cathode-ray pipe, power semiconductor devices, internal parts in light bulbs, etc.

Standard Packing:

Typical bulk packaging includes palletized plastic 5 gallon/25 kg. pails, fiber, and steel drums to 1-ton super sacks in full container (FCL) or truck load (T/L) quantities. Research and sample quantities and hygroscopic, oxidizing, or other air-sensitive materials may be packaged under argon or vacuum. Solutions are packaged in polypropylene, plastic, or glass jars up to palletized 440-gallon liquid totes Special package is available on request.

ATTs’ Molybdenum Lanthanum Alloy is carefully handled to minimize damage during storage and transportation and to preserve the quality of our products in their original condition.

ATT can provide high-performance Molybdenum Lanthanum Alloy with various grades and dimensions. We are dedicated to performing stringent quality control. Whether for research, development, or production, we ensure every single product is of extremely high quality and reproducible.

We are a Molybdenum Lanthanum Alloy supplier. We can produce sheets, plates, foil, tubes, discs, granules, ingots, pellets, pieces, powder, rods, wire, sputtering targets, and numerous other forms and custom shapes. Other shapes are available by request. If you are interested in our products, please contact us now!