Copper is a kind of transition metal with purple luster. It has good ductility, thermal conductivity and electrical conductivity. Pure copper is a soft metal, and its surface has a metallic luster of red and orange when it is just cut. Copper is usually used in cable, electricity, electronic components, building materials and other fields. Copper powder is a kind of metal powder with red luster. Copper powder is usually produced by electrolysis and atomization. Copper powder is flammable and dust is irritating.

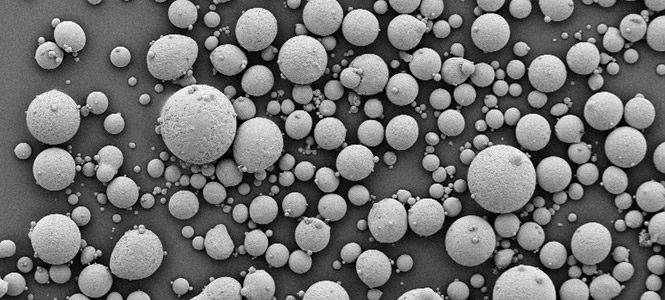

Spherical copper powder refers to copper powder in spherical shape under scanning microscope. It is a high-performance conductive material made of high-purity copper. It has excellent electrical conductivity, thermal stability, chemical stability and good mechanical properties. Compared with ordinary copper powder, spherical copper powder has the characteristics of good powder fluidity and high vibration density. It can be well applied and studied in copper products, thermal spraying field and powder metallurgy process.

The size of spherical copper powder is about 0-15 μ m, 5-25 μ m, 15-45 μ m, 15-53 μ m, 45-75 μ m, 45-105 μ m, 45-150 μ m and 75-150 μ m, which makes it an ideal material for 3D printing and other advanced applications.

High purity (99.9% min.)

Low oxygen (can be less than 500 ppm)

High sphericity (90% min.)

Smooth surface, no satellite

Uniform particle size distribution, excellent flowability (Hall Flow Rate ≤25.0 s/50 g)

High bulk density (≥4.2 g/cm3) and tap density (≥ 5.1 g/cm3)

Laser/electron beam additive manufacturing (SLM/EBM, 3D printing)

Direct laser deposition (DLD)

Powder hot isostatic pressing (HIP)

Metal injection molding (MIM)

Powder metallurgy (PM)

Laser cladding (LC), etc.

The production of spherical copper powder usually involves a process called atomization. Atomization involves converting molten metal into fine droplets and then solidifying them into spherical particles.

The following is a summary of this process:

1. Melting: First, copper is melted at high temperature in a crucible or furnace.

2. Atomization: After copper is melted, it needs to be atomized into small droplets.

There are many methods of atomization, such as:

A. Gas atomization: In this method, an inert gas (such as nitrogen or argon) is used to atomize molten copper. Molten copper is forced through a nozzle into a chamber filled with inert gas. High-pressure gas breaks the molten metal flow into small droplets, which solidify when cooled.

B. Water atomization: This method involves spraying molten copper into a chamber filled with water or other liquid. The sudden contact with the cooling liquid leads to the rapid solidification of molten copper into spherical particles.

C. Centrifugal atomization: This method involves rotating the crucible filled with molten copper at high speed. When the crucible rotates, the molten copper is thrown out, which is broken into fine droplets by centrifugal force and then solidified into spherical particles.

3. Solidification: After copper droplets are atomized, they will quickly solidify into solid spherical particles when cooled. The cooling rate affects the final particle size and shape. Controlling the cooling rate can be achieved by adjusting the atomization gas flow or the distance between the atomization nozzle and the cooling medium.

4. Collection: Spherical copper particles solidified after atomization need to be collected. They can be collected in various ways, such as filtration or cyclone separation systems. These systems separate particles from atomized gas or liquid and collect them in containers.

5. Post-treatment: According to the required properties and applications, the spherical copper powder can be subjected to post-treatment processes, such as annealing, size classification, or surface treatment, to improve the particle size distribution, density, or surface properties.

It is worth noting that the atomization process of producing spherical copper powder is usually carried out in a special industrial environment. The equipment and technology involved may be very complicated, and the parameters such as temperature, pressure, and atomization conditions need to be carefully controlled.

In the field of 3D printing, spherical copper powder is widely used. It can be used to manufacture high-precision and high-strength parts and structures, such as aerospace, automobiles and medical equipment. The high thermal conductivity and chemical stability of spherical copper powder make it have excellent properties in high-temperature environments. In addition, its high strength and wear resistance make it an ideal material for manufacturing complex structures.

In a word, spherical copper powder is a high-performance conductive material, and its unique spherical structure makes it have excellent performance in 3D printing and other advanced applications. The spherical copper powder produced by our company has undergone strict quality control and testing to ensure the reliability of its performance and quality. If you need more information or application about spherical copper powder, please feel free to contact us. We will serve you wholeheartedly.