What do you know about metal Tantalum and Tantalum Alloys? Here is a detailed introduction!

Tantalum is a very precious metal material. Its main characteristics include high melting point, density, hardness, and excellent chemical stability. Tantalum has good high-temperature resistance and can keep its mechanical and chemical properties unchanged in high-temperature environments. Tantalum's chemical stability makes it an ideal corrosion-resistant metal, which can withstand the corrosion of various acids, alkalis, salts, and oxidizing media. In addition, Tantalum has excellent electrical conductivity, thermal conductivity, and formability, which can meet the needs of different fields. It can be said that tantalum is a very excellent material.

So, what about Tantalum Alloy? What is it? In fact, Tantalum Alloy is an alloy formed by mixing Tantalum with other metals. Compared with single Tantalum, Tantalum alloy has further improved its performance on the basis of Tantalum and has a wider application range. Tantalum alloy has higher corrosion resistance and wear resistance than other metal materials.

Our common Tantalum Alloy materials are Tantalum-Niobium Alloy, Tantalum-Tungsten Alloy, and so on. So, what are their characteristics? Tantalum-Niobium Alloy material formed with Niobium has good mechanical properties and high-temperature performance, which can be widely used in the chemical industry, atomic energy, and aerospace fields. Tantalum-Tungsten Alloy materials formed with Tungsten are often used in chemical and nuclear industries because of their excellent mechanical properties and corrosion resistance.

Because of their excellent physical and chemical properties, Tantalum and its alloys are widely used in aerospace, energy, electronics, medical care, the chemical industry, and other fields. In the aerospace field, tantalum and its alloys are widely used to manufacture high-temperature engine parts, liquid rocket engine nozzles, high-temperature components, supersonic aircraft parts, and so on. In the field of energy, Tantalum Alloy is used to manufacture chemical reactors, electrolytic cells, lithium batteries, and other equipment. In the field of electronics, Tantalum and Tantalum Alloys are used to manufacture capacitors, transistors, integrated circuits, and other electronic components. In the medical field, Tantalum Alloy is used to manufacture artificial joints, dental restoration materials, and other medical devices.

Generally speaking, metallic Tantalum and its Tantalum alloys are very important materials, which have many excellent properties and a wide range of applications, bringing us great development space.

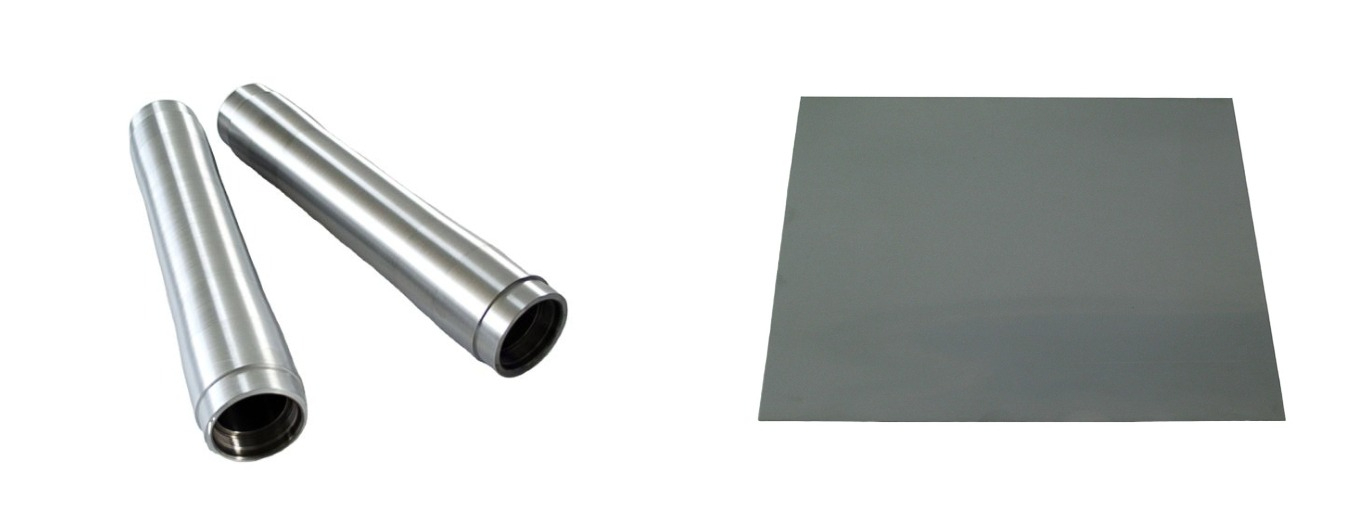

ATT can provide various products of Tantalum and its alloys. We are dedicated to performing stringent quality control. Whether for research, development, or production, we ensure every single product is of extremely high quality and reproducible; even for the most unusual combinations of alloys. We are capable of completing orders as large or small as needed while maintaining high purities of mixed alloys. We cast low-melting reactive materials in a wide range of sizes and we also grind, cut, mill, and DEM materials in a controlled environment. Since we stock our own raw materials, Our services include alloying, pressing, machining, grinding, sheet and wire forming, and reclaiming materials.

We are a tantalum and tantalum alloys supplier. If you are interested in our products, please contact us now!